There are several customizable options and features the Optimizer Plus has to offer. Most of these features and options are in the Optimizer Maintenance Tables in Energy Force and in the Optimizer+ Calendar Tool.

Rules and Considerations

- Users assume all risks associated with modifying the behavior of the Optimizer from its default or recommended settings.

- Only 1 instance of the tool may be running per Windows user session.

Options

Navigate to Supervisor Menu / Maintenance Menu / Optimizer Maintenance / Optimizer+ Calendar Tool and select the Options tab.

- Optimizer Features

- Mode — The Mode determines how the Optimizer functions when generating schedules (which algorithms are used). There are currently two different modes:

- Submodes — Standard operation of the Optimizer. All aspects of the Optimizer (except Summer Fill) and extra features (Exclusions, Tank Groups, etc.) take effect. This mode offers the best scheduling efficiency.

- Summer Fill — The Optimizer does not adhere to extra features, but has robust scheduling efficiency. This mode focuses on delivering many tanks in an area rather than scheduling by severity.

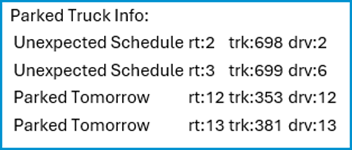

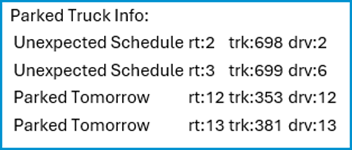

- Predict Parked Trucks — When checked, the Optimizer will run an additional schedule for the next day to see if any trucks are parked. Any routes with parked trucks will be reported in the daily Route Stats email. Predicting parked trucks requires about twice the time for the Optimizer to run. If there is no desire to Predict Park Trucks, then leaving this option unchecked will minimize the time required to generate a schedule each day.

- The parked trucks prediction will be accurate only if:

- The tanks on the schedule today are delivered today.

- There are no changes in the projected weather.

- Override Parked Trucks is not turned on.

- If no additional call-ins are scheduled for delivery tomorrow after the schedule has been created for today.

- If a schedule was not planned for a given day, but some change in the state of the tanks since the day before now requires a schedule run, a notification will be provided in the Daily Route Stats email stating an unanticipated schedule must be run for a given route.

- Warning: Any predictions made during an active exclusion period will be inaccurate due to daily corrections to delivery projections.

- The parked trucks prediction will be accurate only if:

- Mode — The Mode determines how the Optimizer functions when generating schedules (which algorithms are used). There are currently two different modes:

- Skip Weekend Deliveries — When checked, the export process will shift any date-driven tanks (Julian and Will Call) whose closing date falls on Saturday to Friday and Sunday to Monday.

Note: If any tanks fall critical during the weekend, the Optimizer will still attempt a schedule. It may also produce a schedule it identifies as efficient with no critical tanks. Energy Force reports are designed with the option to exclude the weekends from compliance. Additionally, the repeat tanks section of the Daily Route Stats email excludes weekend schedules from the tank count. - Auto-Fill Maximum Fill Level — Allows the maximum fill level to be set to the desired amount. When an Optimizer fills an Auto-Fill tank, it will deliver enough gallons to bring the tank level to this percentage.

Note: If an Auto-Fill tank is larger than a truck and the amount of propane needed to fill it exceeds the truck’s capacity, then the Optimizer will limit the size of the delivery to the truck’s maximum fill amount. - Julian Delivery Window Days — Sets the days before and days after a Julian's scheduled date during which the Optimizer is allowed to consider it for a schedule.

- Call-in Delivery Window Days — Sets the days before and days after a call-in’s scheduled date during which the Optimizer is allowed to consider it for a schedule.

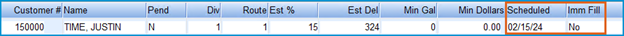

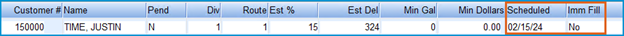

Note: The days before come into play when the Call-In order has a date entered in the Scheduled field and is marked No for Immediate Fill, like in the above example.

Note: The days before come into play when the Call-In order has a date entered in the Scheduled field and is marked No for Immediate Fill, like in the above example. - Tank Setup Time — The average time it takes a driver to perform both the set up and take down at a tank. This does not include the time spent pumping propane, which is calculated from the truck’s pump speed. In other words, this is the time from the arrival at the tank to the time when leaving the tank minus the time spent filling the tank.

Note: Be careful not to over or underestimate when changing this value as it applies to each stop on a schedule. An increase of 5 minutes means a schedule with 10 stops takes an extra 50 minutes to complete.

Note: The days before come into play when the Call-In order has a date entered in the Scheduled field and is marked No for Immediate Fill, like in the above example.

Note: The days before come into play when the Call-In order has a date entered in the Scheduled field and is marked No for Immediate Fill, like in the above example.