Degree Days

What are Heating Degree Days?

- Heating Degree Days (HDD) – The average temperature that falls below 65 degrees. Weather based sites calculate by adding the High + Low temperatures (assumes the high temp for 12 hours and low temp for 12 hours) then divide by 2. Then subtract from 65 to equal the Heating Degree Days.

- Software Degree Day (SDD) – The accumulation of readings throughout the day and then averaged out, which is much more accurate than Heating Degree Days.

What is a K-Factor?

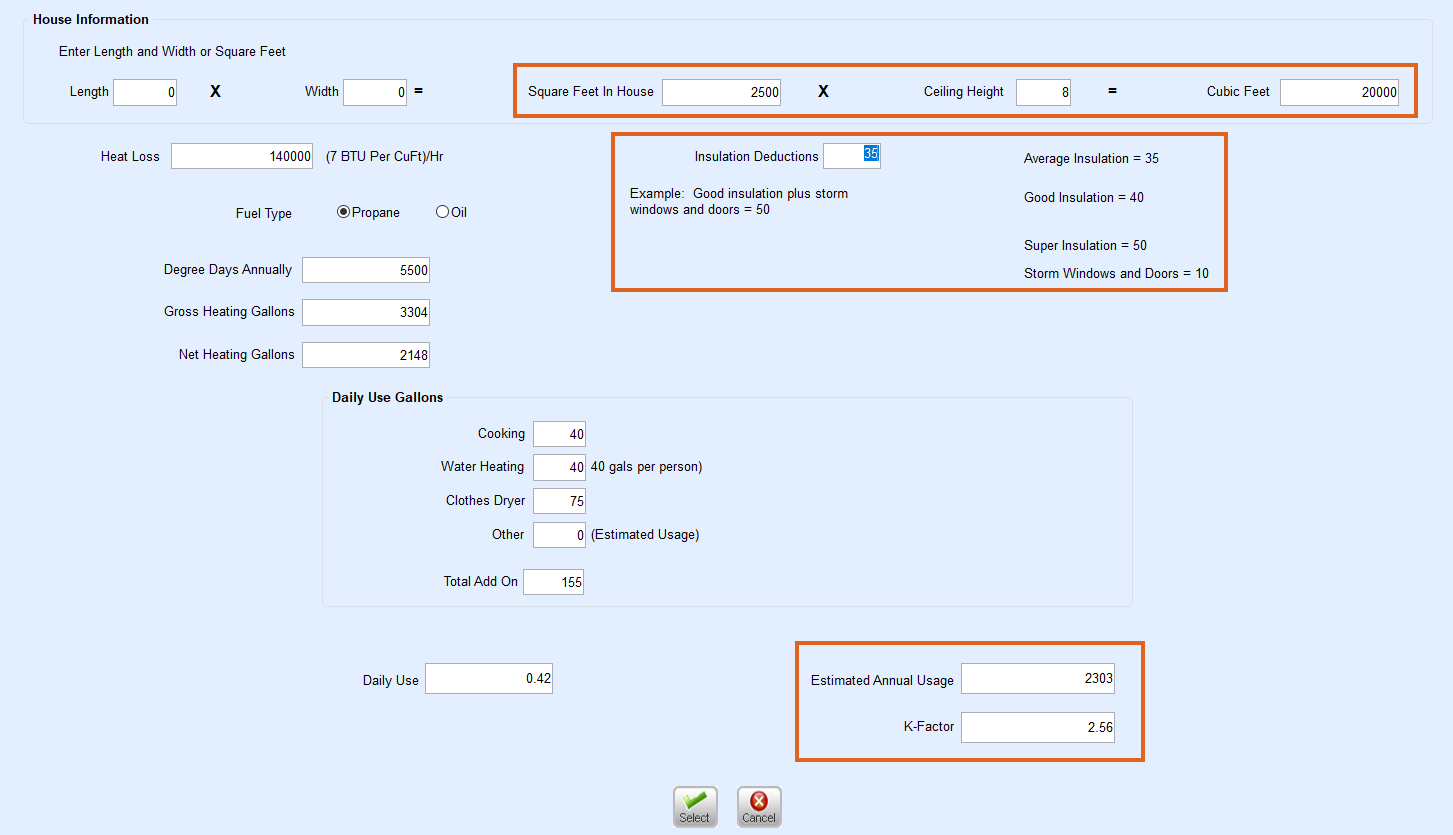

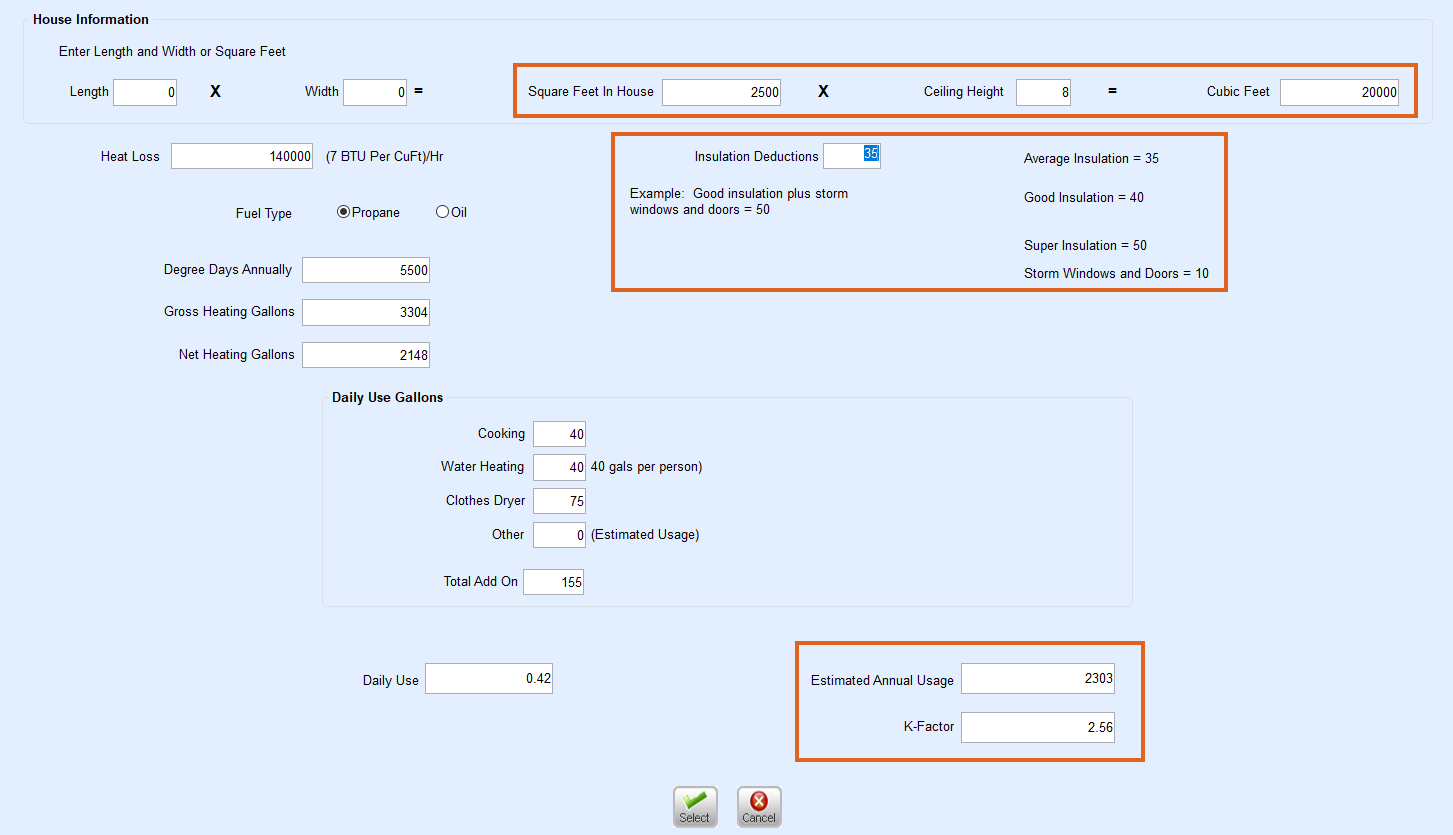

- K-Factor – The number of Degree Days required to burn one gallon of fuel (Burn Rate). K-Factors vary depending upon house information including Square Feet In House, Ceiling Height, Quality of Insulation.

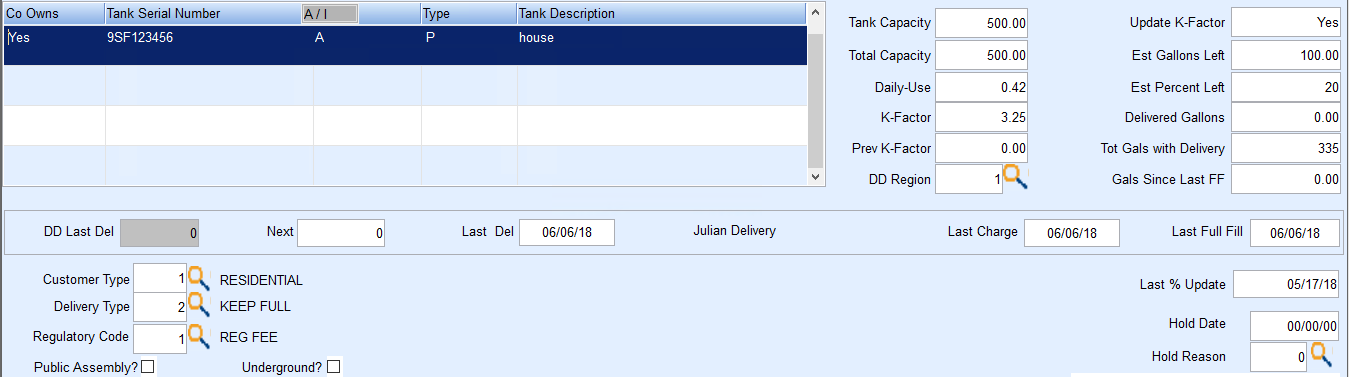

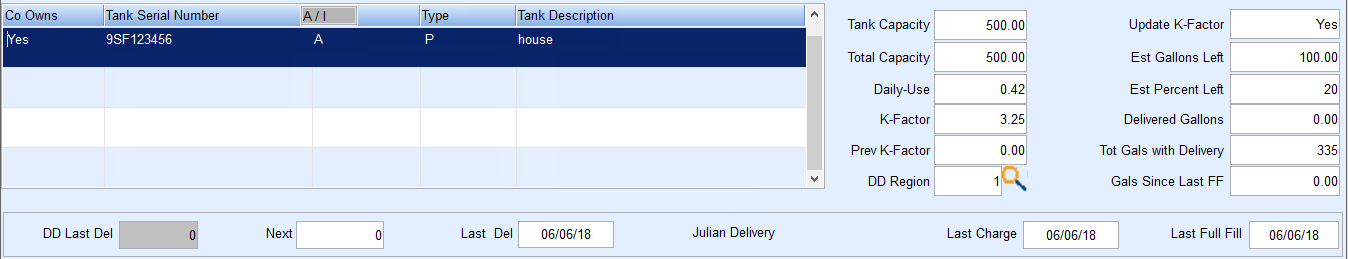

- The K-Factor Calculator can open from any screen in Energy Force by pressing Ctrl+K. Any calculations will need to be noted as they will not save upon closing. However, on the Tank screen in Create mode, double-click in the K-Factor field to open the calculator. Upon choosing Select, the K-Factor and Daily-Use fields will automatically populate based on the information entered in the calculator.

- The K-Factor Calculator can open from any screen in Energy Force by pressing Ctrl+K. Any calculations will need to be noted as they will not save upon closing. However, on the Tank screen in Create mode, double-click in the K-Factor field to open the calculator. Upon choosing Select, the K-Factor and Daily-Use fields will automatically populate based on the information entered in the calculator.

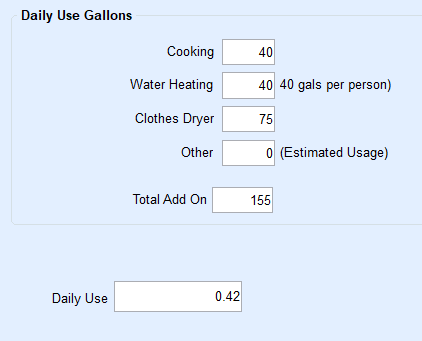

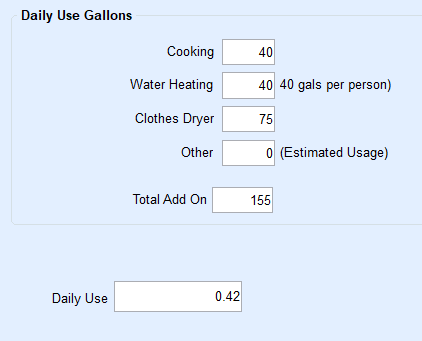

- Daily Use – The propane used by appliances other than home heat including Water Heaters, Clothes Dryers, Cook Stoves, Gas Fireplace/Logs, etc. Daily Use calculations are extremely important for proper estimated propane usage tracking.

- The Daily Use Gallons calculator is located at the K-Factor Calculator screen to input specific information, for example, the number of persons in home for water heaters.

- The Daily Use Gallons calculator is located at the K-Factor Calculator screen to input specific information, for example, the number of persons in home for water heaters.

How do they work together?

- When a tank is first set up, the K-Factor is calculated with Next DD (Degree Day) or when the tank reaches 20%.

- Degree Days are updated daily via SDD during Automated Tasks or manually input through the Posting Menu.

- When processed, Delivery Type 2 tank percentages are depleted based on the K-Factor value and if applicable by Daily Use Gallons.

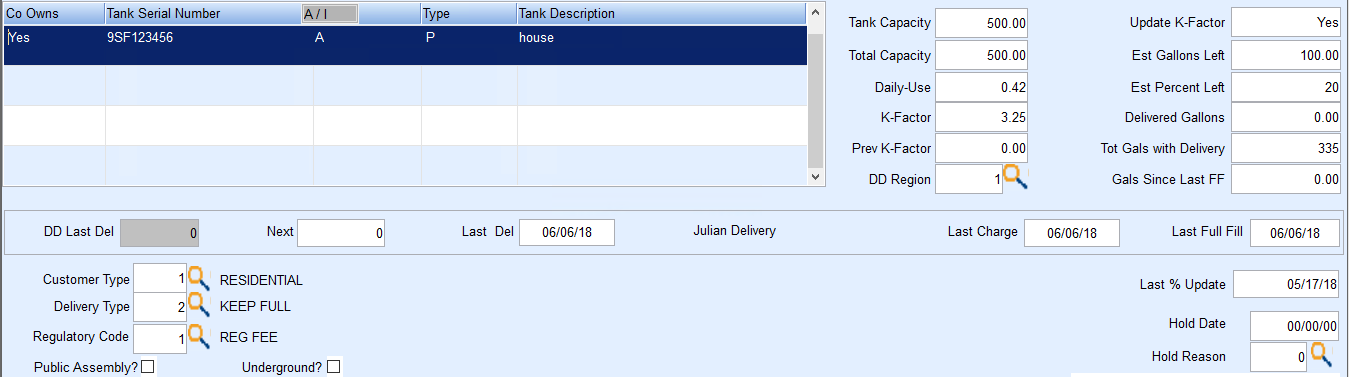

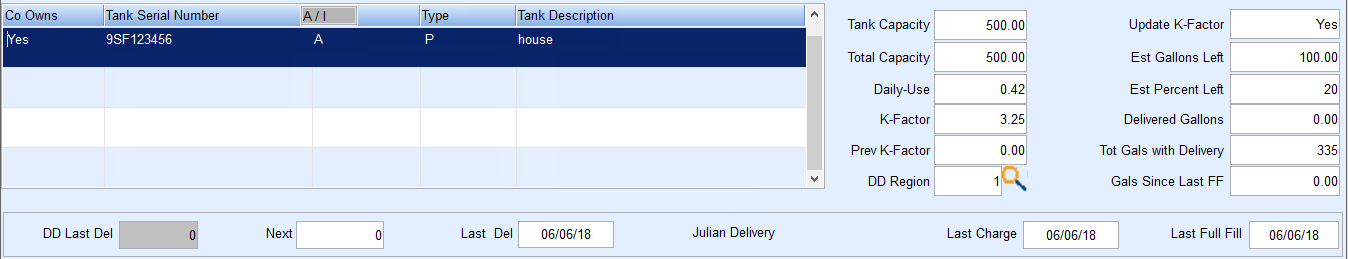

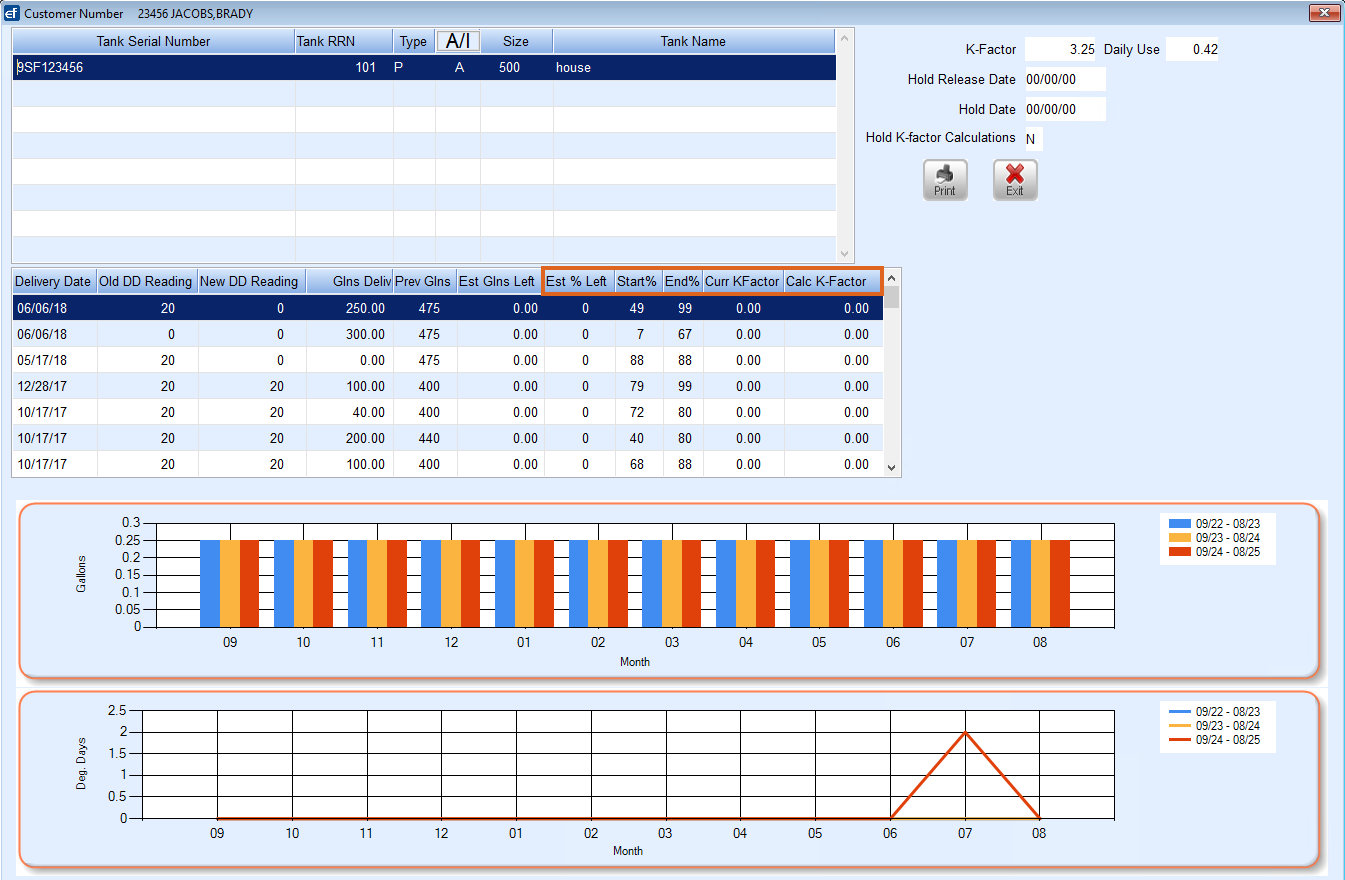

- In the example below, 30 degree days were posted. The system reduced the Estimated Percentage Left using both the K-Factor and .42 Daily-Use Gallons for one day's usage.

Calculations for New Deliveries

- As sales are made, readings are stored in the Tank Readings screen based on delivery dates and actual tank values at the time of delivery.

- K-Factors are re-calculated based on the percentage change threshold (stored in the Division table) and the data from the last two deliveries. While percentage updates are included in the recalculation process, the initial calculation cannot be triggered by a percentage update alone. A delivery of gallons is required to initiate the first recalculation.

- The averages of 3 or more deliveries helps to eliminate large fluctuations.

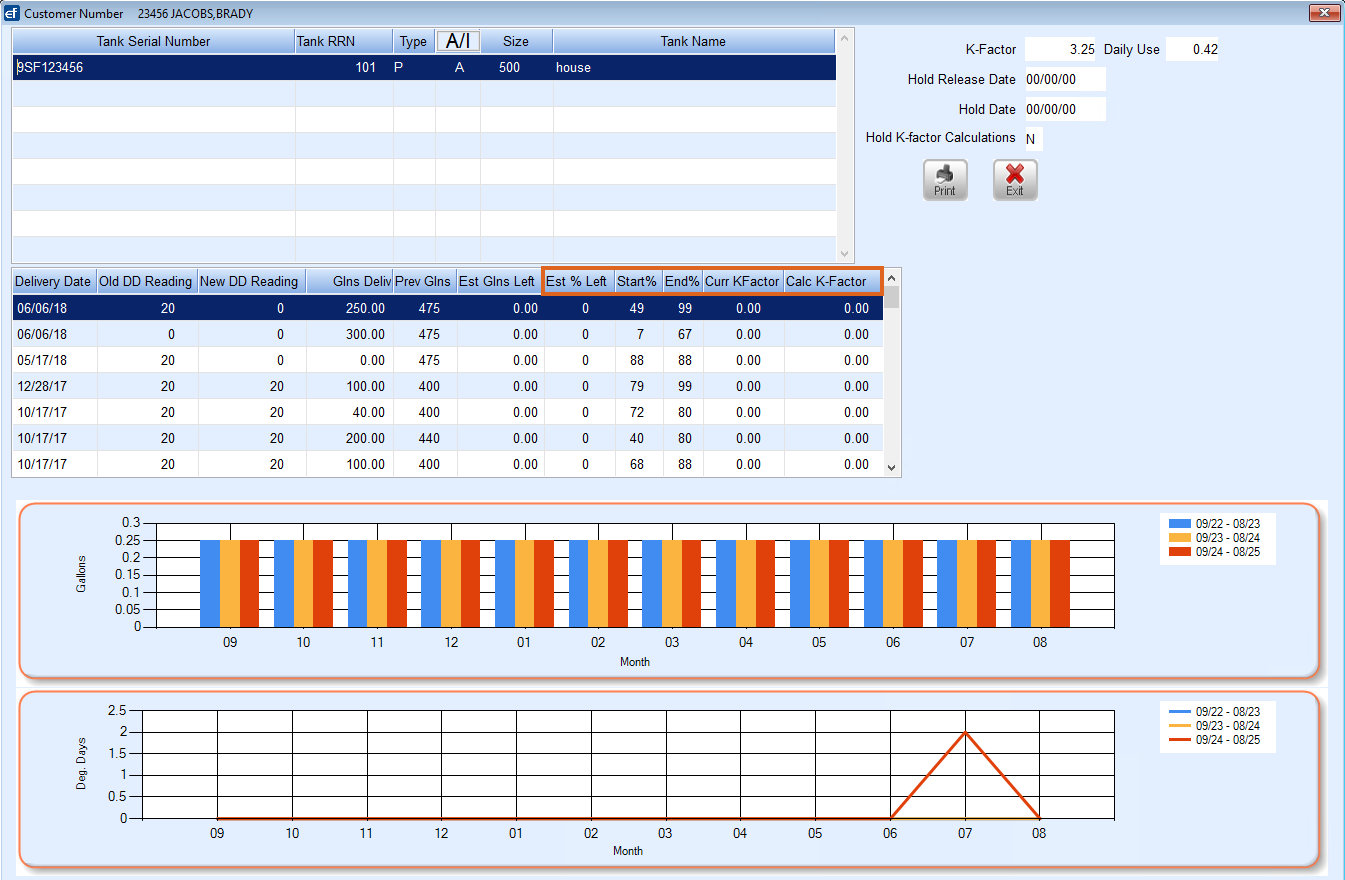

Tank Reading Screen

- The Tank Reading screen displays current Delivery readings as well as Estimated Percent.

- Current K-Factor vs. Calculated K-Factor is based on % to change and 2 previous deliveries.

- Estimated % Left vs. Start % should be within a 10% range.

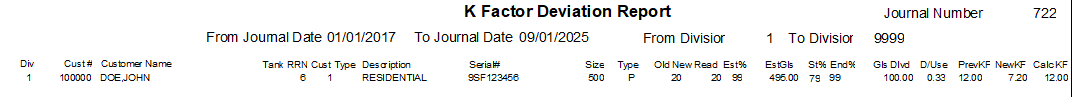

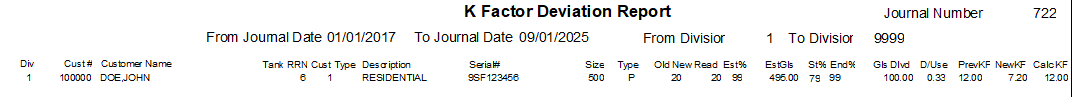

K-Factor Deviations

When a K-Factor wants to adjust by a value greater than what’s allowed in the Division table (generally 1.0 or greater), a report generates at the end of each sales journal if any deviations occurred while posting sales to notify of the deviation for review.

- This report needs to be monitored daily and propane usage investigated for those most vulnerable for future runouts.

- Has something changed?

- Number of residents

- Added another room to house

- Wood burners or alternative heat source

- Read more about K-Factor Deviations on the Energy Force Help Center.

Update Information

- Contact customers regarding major changes in usage and log all information in a tickler.

- Modify Tank information as needed, or manually adjust a K-Factor to alter the depletion rate. While manual K-Factor changes immediately affect the depletion rate, the next calculation (whether triggered by a percentage update or a delivery) will revert to using the previous K-Factor for that calculation.

Other Useful Tips

- Update DD Readings Daily, even in the summer time when DD’s do not occur as well as Daily Usage to avoid experiencing a run out in summer due to daily use.

- Run K-Factor Deviation and Management reports as part of a daily routine to ensure employees are reviewing the data.

- Run K-Factor Delivery Analysis reports to review runouts and percent updates.

- A great K-Factor tank, is one that uses propane for the entire heating season.

- A customer must participate in reviewing heat usage if utilizing supplemental heat to avoid run outs, as the K Factor will never be correct.

- Non-ideal K-Factor Candidates

- 120 gallon tanks are not good candidates for a K-Factor because they are not used consistently for heat and may have a high daily usage rate.

- Julian’s (interval schedules or day of the month, etc.) and Call In are also tanks that do not qualify for K-Factor.

- Shop, garage, dairy barns, poultry, pool heaters and temporary heat tanks are not good K-Factor tanks as the usage pattern is not consistent.

- Remote Tank Monitors work great with tanks that do not quality as good K-Factor tanks.